KINGBRIGHT SC15-11SRWA

Specifications

Manufacturer

Kingbright

Manufacturers Part #

SC15-11SRWA

Industry Aliases

SC15-11SRWA

Sub-Category

Segmented LED Displays

Packaging

Tube

Factory Pack Quantity

15

Datasheet

Extracted Text

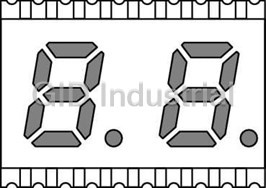

SC15-11SRWA 38.1 mm (1.5 inch) Single Digit Numeric Display DESCRIPTIONS PACKAGE DIMENSIONS z The Super Bright Red source color devices are made with Gallium Aluminum Arsenide Red Light Emitting Diode z Electrostatic discharge and power surge could damage the LEDs z It is recommended to use a wrist band or anti-electrostatic glove when handling the LEDs z All devices, equipments and machineries must be electrically grounded FEATURES z 1.5 inch digit height z Low current operation z Excellent character appearance z High light output z Easy mounting on P.C. boards or sockets z Mechanically rugged z Standard: gray face, white segment z RoHS compliant APPLICATIONS z Home and smart appliances z Display time and digital combination z Industrial and instrumental applications z Numeric status ATTENTION Observe precautions for handling electrostatic discharge sensitive devices Notes: 1. All dimensions are in millimeters (inches), Tolerance is ±0.25(0.01")unless otherwise noted. 2. The specifications, characteristics and technical data described in the datasheet are subject to change without prior notice. SELECTION GUIDE [1] Iv (ucd) @ 10mA Emitting Color Part Number Lens Type Description (Material) Min. Typ. 52000 97000 Common Cathode, ■ Super Bright Red SC15-11SRWA White Diffused Rt. Hand Decimal (GaAlAs) *14000 *28000 Notes: 1. Luminous intensity / luminous Flux: +/-15%. * Luminous intensity value is traceable to CIE127-2007 standards. Page 1 / 5 © 2018 Kingbright. All Rights Reserved. Spec No: DSAP4989 / 1301000805 Rev No: V.1A Date: 05/31/2018 SC15-11SRWA ELECTRICAL / OPTICAL CHARACTERISTICS at T =25°C A Value Parameter Symbol Emitting Color Unit Typ. Max. Wavelength at Peak Emission I = 10mA λ Super Bright Red 655 - nm F peak [1] Dominant Wavelength I = 10mA λ Super Bright Red 640 - nm F dom Spectral Bandwidth at 50% Φ REL MAX Δλ Super Bright Red 20 - nm I = 10mA F Capacitance C Super Bright Red 45 - pF Forward Voltage I = 10mA (Segment) 3.6 4.6 F [2] V Super Bright Red V F Forward Voltage I = 10mA (DP) 1.8 2.3 F Reverse Current (V = 5V) (Per chip) I Super Bright Red - 10 uA R R Notes: 1. The dominant wavelength (λd) above is the setup value of the sorting machine. (Tolerance λd : ±1nm. ) 2. Forward voltage: ±0.1V. 3. Wavelength value is traceable to CIE127-2007 standards. 4. Excess driving current and / or operating temperature higher than recommended conditions may result in severe light degradation or premature failure. ABSOLUTE MAXIMUM RATINGS at T =25°C A Parameter Symbol Value Unit Power Dissipation (Per chip) P 75 mW D Reverse Voltage (Per chip) V 5 V R Junction Temperature T 115 °C j Operating Temperature T -40 to +85 °C op Storage Temperature T -40 to +85 °C stg DC Forward Current (Segment) 30 I mA F DC Forward Current (DP) 30 Peak Forward Current (Segment) 155 [1] I mA FM Peak Forward Current (DP) 155 Electrostatic Discharge Threshold (HBM) 3000 V - [2] Lead Solder Temperature 260°C For 3-5 Seconds Notes: 1. 1/10 Duty Cycle, 0.1ms Pulse Width. 2. 2mm below package base. 3. Relative humidity levels maintained between 40% and 60% in production area are recommended to avoid the build-up of static electricity – Ref JEDEC/JESD625-A and JEDEC/J-STD-033. Page 2 / 5 © 2018 Kingbright. All Rights Reserved. Spec No: DSAP4989 / 1301000805 Rev No: V.1A Date: 05/31/2018 SC15-11SRWA TECHNICAL DATA RELATIVE INTENSITY vs. WAVELENGTH Red 100% T = 25 °C a 80% 60% 40% 20% 0% 350 400 450 500 550 600 650 700 750 800 Wavelength (nm) SUPER BRIGHT RED (SEGMENT) Forward Current vs. Luminous Intensity vs. Forward Current Derating Curve Luminous Intensity vs. Forward Voltage Forward Current Ambient Temperature 20 2.5 50 2.5 T = 25 °C a T = 25 °C a 16 2.0 40 2.0 12 1.5 30 1.5 8 1.0 20 1.0 4 0.5 10 0.5 0 0.0 0 0.0 3.4 3.5 3.6 3.7 3.8 3.9 04 8 12 16 20 -40 -20 0 20 406080 100 -40 -20 0 204060 80 100 Forward voltage (V) Forward current (mA) Ambient temperature (°C) Ambient temperature (°C) SUPER BRIGHT RED (DP) Forward Current vs. Luminous Intensity vs. Forward Current Derating Curve Luminous Intensity vs. Forward Voltage Forward Current Ambient Temperature 20 2.5 50 2.5 T = 25 °C a T = 25 °C a 16 2.0 40 2.0 12 1.5 30 1.5 8 1.0 20 1.0 4 0.5 10 0.5 0 0.0 0 0.0 1.3 1.5 1.7 1.9 2.1 2.3 04 8 12 16 20 -40 -20 0 20 406080 100 -40 -20 0 204060 80 100 Forward voltage (V) Forward current (mA) Ambient temperature (°C) Ambient temperature (°C) Page 3 / 5 © 2018 Kingbright. All Rights Reserved. Spec No: DSAP4989 / 1301000805 Rev No: V.1A Date: 05/31/2018 Forward current (mA) Relative Intensity (a. u.) Forward current (mA) Luminous intensity normalised at Luminous intensity normalised at 10 mA 10 mA Permissible forward current (mA) Permissible forward current (mA) Luminous intensity normalised Luminous intensity normalised at at Ta = 25 °C Ta = 25 °C SC15-11SRWA RECOMMENDED WAVE SOLDERING PROFILE Soldering General Notes 1. Through-hole displays are incompatible with reflow soldering. 2. If components will undergo multiple soldering processes, or other processes where the components may be subjected to intense heat, please check with Kingbright for compatibility. CLEANING 1. Mild "no-clean" fluxes are recommended for use in soldering. 2. If cleaning is required, Kingbright recommends to wash components with water only. Do not use harsh organic solvents for cleaning because they may damage the plastic parts . 3. The cleaning process should take place at room temperature and the devices should not be washed for more than one minute. Notes: 4. When water is used in the cleaning process, Immediately 1. Recommend pre-heat temperature of 105°C or less (as measured with a thermocouple remove excess moisture from the component with forced-air attached to the LED pins) prior to immersion in the solder wave with a maximum solder bath temperature of 260°C drying afterwards. 2. Peak wave soldering temperature between 245°C ~ 255°Cfor 3 sec (5 sec max). 3. Do not apply stress to the epoxy resin while the temperature is above 85°C. 4. Fixtures should not incur stress on the component when mounting and during soldering process. 5. SAC 305 solder alloy is recommended. 6. No more than one wave soldering pass. 7. During wave soldering, the PCB top-surface temperature should be kept below 105°C. PACKING & LABEL SPECIFICATIONS THROUGH HOLE DISPLAY MOUNTING METHOD Lead Forming 1. Do not bend the component leads by hand without proper tools. The leads should be bent by clinching the upper part of the lead firmly such that the bending force is not exerted on the plastic body. Installation 1. The installation process should not apply stress to the lead terminals. 2. When inserting for assembly, ensure the terminal pitch matches the substrate board's hole pitch to prevent spreading or pinching the lead terminals. (Fig.1) 3. The component shall be placed at least 5mm from edge of PCB to avoid damage caused excessive heat during wave soldering.(Fig.2) Page 4 / 5 © 2018 Kingbright. All Rights Reserved. Spec No: DSAP4989 / 1301000805 Rev No: V.1A Date: 05/31/2018 SC15-11SRWA CIRCUIT DESIGN NOTES 1. Protective current-limiting resistors may be necessary to operate the LEDs within the specified range. 2. LEDs mounted in parallel should each be placed in series with its own current-limiting resistor.(Fig.3) 3. The driving circuit should be designed to protect the LED against reverse voltages and transient voltage spikes when the circuit is powered up or shut down. 4. The safe operating current should be chosen after considering the maximum ambient temperature of the operating environment. 5. Prolonged reverse bias should be avoided, as it could cause metal migration, leading to an increase in leakage current or causing a short circuit. PRECAUTIONARY NOTES 1. The information included in this document reflects representative usage scenarios and is intended for technical reference only. 2. The part number, type, and specifications mentioned in this document are subject to future change and improvement without notice. Before production usage customer should refer to the latest datasheet for the updated specifications. 3. When using the products referenced in this document, please make sure the product is being operated within the environmental and electrical limits specified in the datasheet. If customer usage exceeds the specified limits, Kingbright will not be responsible for any subsequent issues. 4. The information in this document applies to typical usage in consumer electronics applications. If customer's application has special reliability requirements or have life-threatening liabilities, such as automotive or medical usage, please consult with Kingbright representative for further assistance. 5. The contents and information of this document may not be reproduced or re-transmitted without permission by Kingbright. 6. When any special process such as potting is required for LED assembly, please consult with Kingbright representative before proceeding. 7. All design applications should refer to Kingbright application notes available at http://www.KingbrightUSA.com/ApplicationNotes Page 5 / 5 © 2018 Kingbright. All Rights Reserved. Spec No: DSAP4989 / 1301000805 Rev No: V.1A Date: 05/31/2018

Frequently asked questions

How does Electronics Finder differ from its competitors?

Is there a warranty for the SC15-11SRWA?

Which carrier will Electronics Finder use to ship my parts?

Can I buy parts from Electronics Finder if I am outside the USA?

Which payment methods does Electronics Finder accept?

Why buy from GID?

Quality

We are industry veterans who take pride in our work

Protection

Avoid the dangers of risky trading in the gray market

Access

Our network of suppliers is ready and at your disposal

Savings

Maintain legacy systems to prevent costly downtime

Speed

Time is of the essence, and we are respectful of yours

Manufacturers

Manufacturers

What they say about us

FANTASTIC RESOURCE

One of our top priorities is maintaining our business with precision, and we are constantly looking for affiliates that can help us achieve our goal. With the aid of GID Industrial, our obsolete product management has never been more efficient. They have been a great resource to our company, and have quickly become a go-to supplier on our list!

Bucher Emhart Glass

EXCELLENT SERVICE

With our strict fundamentals and high expectations, we were surprised when we came across GID Industrial and their competitive pricing. When we approached them with our issue, they were incredibly confident in being able to provide us with a seamless solution at the best price for us. GID Industrial quickly understood our needs and provided us with excellent service, as well as fully tested product to ensure what we received would be the right fit for our company.

Fuji

HARD TO FIND A BETTER PROVIDER

Our company provides services to aid in the manufacture of technological products, such as semiconductors and flat panel displays, and often searching for distributors of obsolete product we require can waste time and money. Finding GID Industrial proved to be a great asset to our company, with cost effective solutions and superior knowledge on all of their materials, it’d be hard to find a better provider of obsolete or hard to find products.

Applied Materials

CONSISTENTLY DELIVERS QUALITY SOLUTIONS

Over the years, the equipment used in our company becomes discontinued, but they’re still of great use to us and our customers. Once these products are no longer available through the manufacturer, finding a reliable, quick supplier is a necessity, and luckily for us, GID Industrial has provided the most trustworthy, quality solutions to our obsolete component needs.

Nidec Vamco

TERRIFIC RESOURCE

This company has been a terrific help to us (I work for Trican Well Service) in sourcing the Micron Ram Memory we needed for our Siemens computers. Great service! And great pricing! I know when the product is shipping and when it will arrive, all the way through the ordering process.

Trican Well Service

GO TO SOURCE

When I can't find an obsolete part, I first call GID and they'll come up with my parts every time. Great customer service and follow up as well. Scott emails me from time to time to touch base and see if we're having trouble finding something.....which is often with our 25 yr old equipment.

ConAgra Foods